One more partner is added to the presentation list of the CO-ADAPT consortium. This time we will meet the people behind BNP, in a more detailed description of their involvement and their vision of the project.

BNP is an Italian SME company which develops and manufactures advanced ergonomic solutions and components for the assembly and tightening phases in manufacturing sector industrial processes (mainly automotive and BNP goods), since 1995.

In recent years, invested a lot in new technologies and innovative materials developing high-tech products with competitive prices. BNP’s mission is to improve production processes by increasing ergonomics contents in their solutions. By using industrial collaborative robots, technological innovation improves operator working conditions, respecting principles of ergonomics.

BNP know-how includes constant effort in the design of high technological value and high usability systems. All of their assembly equipment can be digitally managed by a co-developed integrative software, allowing process quality control using Big Data analysis.

In 2017, BNP won the “Innovation in robotics” award at Mecspe Fair in Parma – Italy. BNP collaborates with several local industrial partners allowing a full coverage of all the technical needs. In particular, BNP is supporting UNIPD within the CO-ADAPT project, by designing and building the experimental ergonomic workstation.

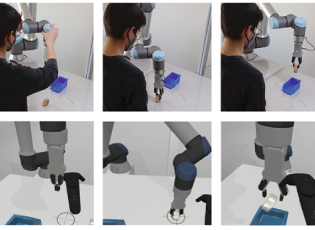

The main focus of BNP is designing, developing, and building ergonomic solutions adopting a human-centered perspective. Furthermore, considering the mission of CO-ADAPT, which aims at increasing the elderly operator’s well-being and safety at the workplace. BNP designed and built an Adaptive Assembly Workstation with a collaborative robot that will be the base for all the cutting-edge technologies developed by partners. Indeed, BNP has strong expertise in manufacturing ergonomics, in designing and evaluating symbiotic systems (i.e., technologies capable to adapt their functioning in real-time on the basis of the state of users, i.e., stress and workload).

The main role of the BNP, throughout the whole project, comprises the development of an Adaptive Assembly Workstation prototype, equipped with a collaborative robot (cobot), as well as a full-integrated system. In cooperation with UNIPD, the aim is to identify reliable metrics of mental workload and stress on the basis of which the operating of the AAW will support users. The test plan includes the possibility to carry out in a real work environment where senior workers, supported by the AAW and the cobot, will accomplish real working tasks.

“We are constantly focused on operator health and safety, which is in the center of all our technical solutions. We believe that next frontier of industrial equipment conceptual design will be focused on aging workers, and we are really involved in the CO-ADAPT project, which is a natural evolution of our company vision. The collection of data during the development of the project will be fundamental for converting the experiments into real-life usage.” Giuseppe Testa, Project Manager, Co-owner, BNP

“Our aim is to spread our long-term experience in ergonomics and human-centric approach, by directly involving end users, in designing and developing breakthrough working technologies (i.e., Adaptive Assembly Workstation with collaborative robotic). The main target is to convert the experimental phase in daily life, with user-friendly technologies in the industrial environment.” Andrea Ragazzon, Project Manager, BNP